intelligenta lösningar för byggpraxis,

isolering ock högeffektiv isoleringsmaskin

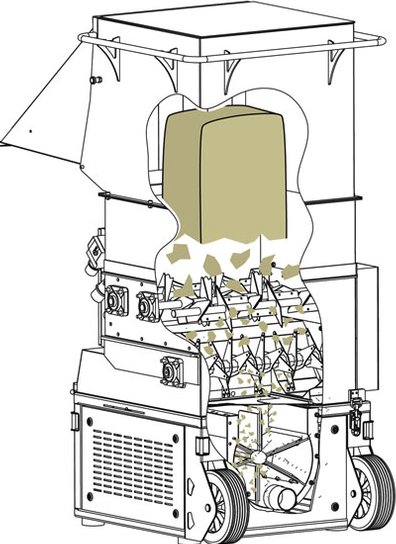

EM300 insulation blowing machine

- Tough design

- High ergonomics

- Reduced dust outlet by strip curtains

- High mobility

- Building site suited tyres

- Maintainability

The EM300 series is stands out with its versatility relating to processing materials. With this machine nearly all licensed insulation blowing materials can be processed. For instance cellulose, wood fibre, mineral wool, granules, bulk material or composite materials.

The machine can be provided with light or three-phase current.

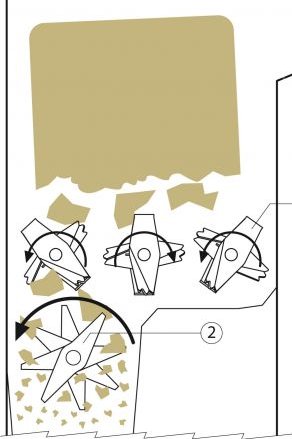

The EM300 has an innovative conditioning unit with two active layers. In the first layer the three crusher shafts make a steady shredding sure – also for high compressed raw material.

The fine preparation is made in the second conditioning layer with the fast rotating shredder unit. The material is transported to the air lock afterwards and is blown out from there.

The stainless steel made air lock with ventilation distinguishes itself with a very good sealing with small loss of pressure and high processing speed.

The extremely high air power is generated by turbine or radial compressors (depending on machine type) or with a combination of both.

All important machine settings can be adjusted from the injection point with the cable or the remote control.

The following configurations can be ordered:

- EM320-2×230V/7,0kW: 3 high-powered radial compressors

- EM325-3×230V/10,3kW: 5 high-powered radial compressors

- EM340-400V/7,3kW: 3 high-powered radial compressors

- EM345-400V/1×230V/10,6kW: 5 high-powered radial compressors

- EM360-400V/6,0kW: Turbine

- EM365-400V/1×230V/9,2kW: Turbine and 2 high-powered radial compressors

Important features:

- Tough design

- High ease of use

- Highest performance

- Ergonomics

- Filling comfort with support for bags (foldaway)

- Reduced dust outlet by strip curtains

- More dust reduction possible with active aspiration

- Vertical filling option by removable coverage

- High mobility

- Building site suited tyres

- Maintainability

- Good access to all machine parts by modular design and swivelling machine top

Compatible blowing insulation materials

The EM300 insulation blowing machine has a very high compatibilty concerning to insulation materials. The following materials can be applied:

Cellulose insulation materials:

Isofloc L, Isofloc LW, isofloc LM, Dämmstatt, Finefloc, Climacell, Pavafloc, Climatizer Plus, isodan CI 040, Thermofloc, Unifloc, Isocell, Wolfinger Dämmzellulose, Austrozell, Ekofiber, Bellouate, Cellisol, Isol’quate, Klima-Tec-Flock, Poesis-Floc, Biocell, NR Gaia, Univercell, Ouateco, Warmcell, Biocell, Icell, Isofiber, Termex, Selluvilla, Ekovilla, Cellaouate, Isoprof, Franceouate, Ecocel, Nesocell, Ecovata, Greenfiber, Cel-Pak, Arctic Fiber, Mono-Therm, Norhern Fiber, United Fibers, Igloo, Iglu, Applegate, EC cellulose, Forest wool, Nu-Wool, Fiberlite, Advanced Fibre cellulose, Champion, Zellofix, AislaNat, etc.

Woodfibre insulation materials:

isofloc woodfiber, Steicozell, Thermofibre, Thermocell,

Termoträ, Jasmin, HOIZ, etc.

Mineral fibre insulation materials (glass wool or rock wool):

Rockwool, Ecofibre BLT3 – BLT5 – BLT9, Paroc BLT7, Supafil Wall 034, Supafil Loft 045, Greenguard, Comblissimo, Rathifloc, Astratherm, Isomat, Teko-Flock, Indi-Flock, Dossolan Thermique, Fibrexpan, Ecofibre KD, Tecwool F, Projiso etc.

Mineral granules:

SLS20, Hyperlite, Hyperdämm, Thermoperl, Thermofill S – S40, Bachl Perlite, Perli-Fil,l, Perlifill-F, Extraperl H4, Fillrock KD, Isomat ISG, Liapor, etc.

EPS granules:

isofloc pearl, Rigibead, HK35, HK33, Neopor, Joma Perl, Rathipur KD, Bodiflock XPS, EASY-FILL 034 – 033, DämmPerl 035, Granublow 035, etc.

Other insulation materials:

Neptutherm (sea weed), Agricell (weed), Aerogel (nano gel), Durolan, Duroperl 35, HDW ED (hemp), etc.

Our insulation blowing machines

Download an overview of our insulation blowing machines